Exploring 2025 Glass Hermetic Seal Materials: Types, Benefits, and Manufacturers

Release time:2025-09-05

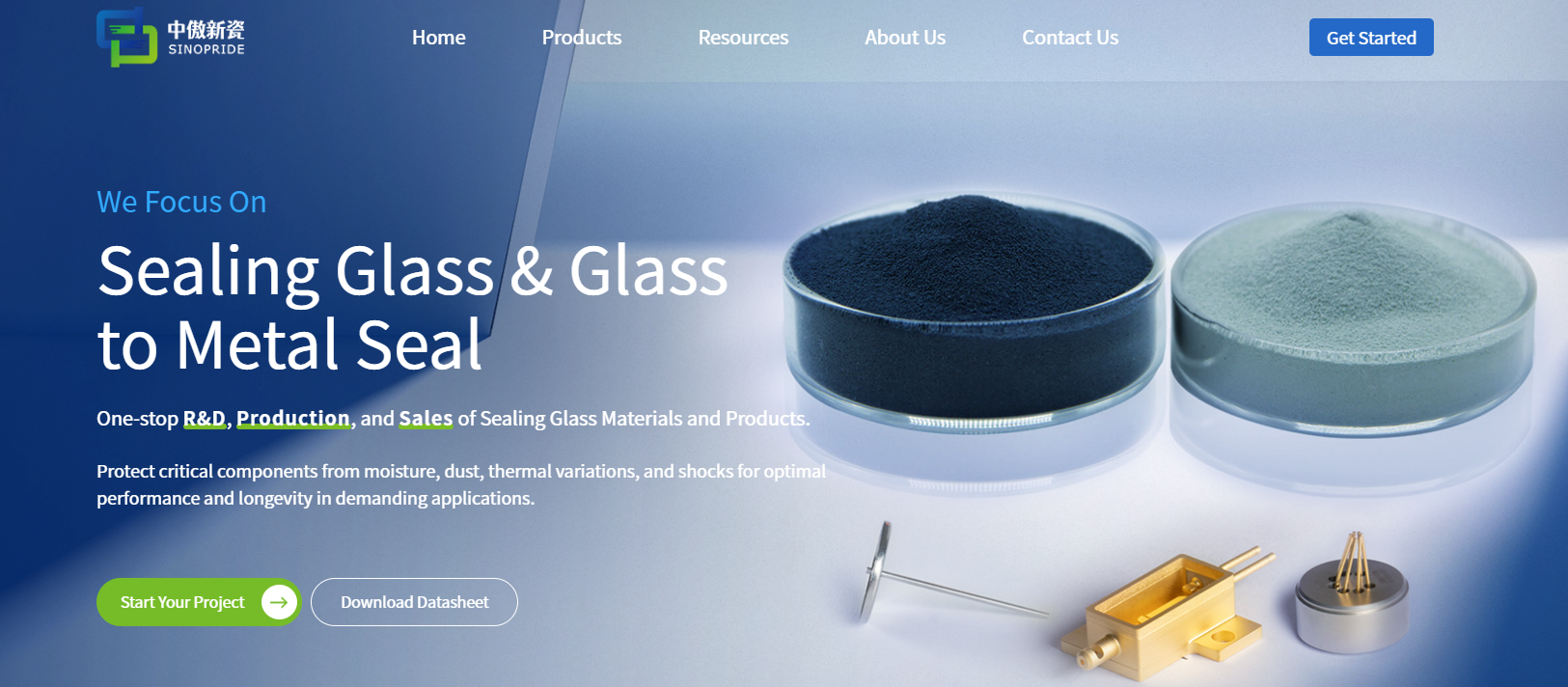

In 2025, glass hermetic seals remain crucial in industries like aerospace, medical devices, and electronics, where reliability and protection against environmental factors are essential. Hermetic seals are designed to create airtight and waterproof enclosures, ensuring that sensitive components are shielded from gases, liquids, and contaminants. The main types of glass hermetic seals include Kovar sealing glass, iron-sealed glass, and glass preforms, each offering unique benefits depending on the application.

what does hermetically sealed mean?

-What is hermetically sealed glass?

-What is the difference between airtight and hermetically?

-What is an example of a hermetic seal?

What are the different types of hermetic seals?

-Kovar sealing glass

-Iron-sealed glass

-Glass preform

what are the hermetic solutions:glass to metal seal

-Benefits of Glass-Metal Sealing Solutions

-Customized Sealing Solutions

2025 Glass to metal seal manufacturers Recommendations

Conclusion

What Does Hermetically Sealed Mean?

A hermetic seal refers to an airtight, airtight, and waterproof enclosure designed to prevent the penetration of gases, liquids, or other external contaminants. The concept of hermetic sealing is critical in many industrial applications where long-term reliability and safety are paramount. By sealing off a device or container, hermetic sealing ensures that the contents inside remain protected from environmental factors.

What is Hermetically Sealed Glass?

Hermetically sealed glass refers to glass that is sealed in a way that ensures complete isolation from the surrounding environment. This type of glass seal is often used in sensitive applications like electronics, sensors, medical devices, and other high-tech systems where exposure to air, moisture, or contaminants can impair the performance and longevity of the device. The glass can be hermetically sealed with metals like Kovar, a nickel-cobalt alloy, or other sealing materials that form a perfect barrier.

What is the Difference Between Airtight and Hermetically Sealed?

The terms "airtight" and "hermetically sealed" are often used interchangeably, but there is a subtle difference. While both airtight and hermetically sealed enclosures prevent air from entering or exiting, a hermetic seal goes one step further to ensure that no contaminants—such as moisture, gases, or chemicals—can penetrate. Therefore, while all hermetic seals are airtight, not all airtight seals are hermetic.

What is an Example of a Hermetic Seal?

A common example of a hermetic seal is found in electronic components such as semiconductors, diodes, or microchips. These components are often encapsulated in glass packages with a hermetic seal, ensuring that they remain free from moisture, dust, or corrosive gases that could damage their delicate circuits. Another example is the glass vials used in pharmaceutical packaging, where the integrity of the seal prevents contamination and preserves the contents' sterility.

What Are the Different Types of Hermetic Seals?

Hermetic sealing technologies have advanced significantly over the years. In 2025, there are several types of hermetic seals, each with specific benefits and applications. Let’s take a closer look at some of the most common types of hermetic seals used in the industry.

Kovar Sealing Glass

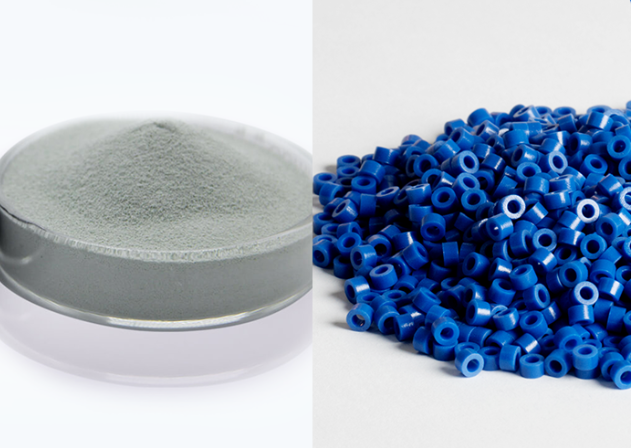

Kovar is one of the most popular sealing materials used in hermetic glass-to-metal seals. It is an iron-nickel-cobalt alloy that has a similar coefficient of thermal expansion to that of glass, making it an ideal material for sealing glass to metals without cracking. Kovar is commonly used for high-performance applications such as aerospace, military, and medical devices where extreme reliability and durability are required. Kovar seals provide a long-lasting, reliable seal that can withstand temperature changes and mechanical stress.

Iron-Sealed Glass

Iron-sealed glass is another common option for hermetic sealing. Iron’s relatively low cost, excellent compatibility with glass, and ability to form a strong bond with many types of glass make it an appealing choice for mass-market applications. These seals are frequently used in consumer electronics and automotive applications. However, iron-sealed glass is typically not as durable as Kovar in high-stress environments, and it is more prone to degradation under extreme temperature fluctuations.

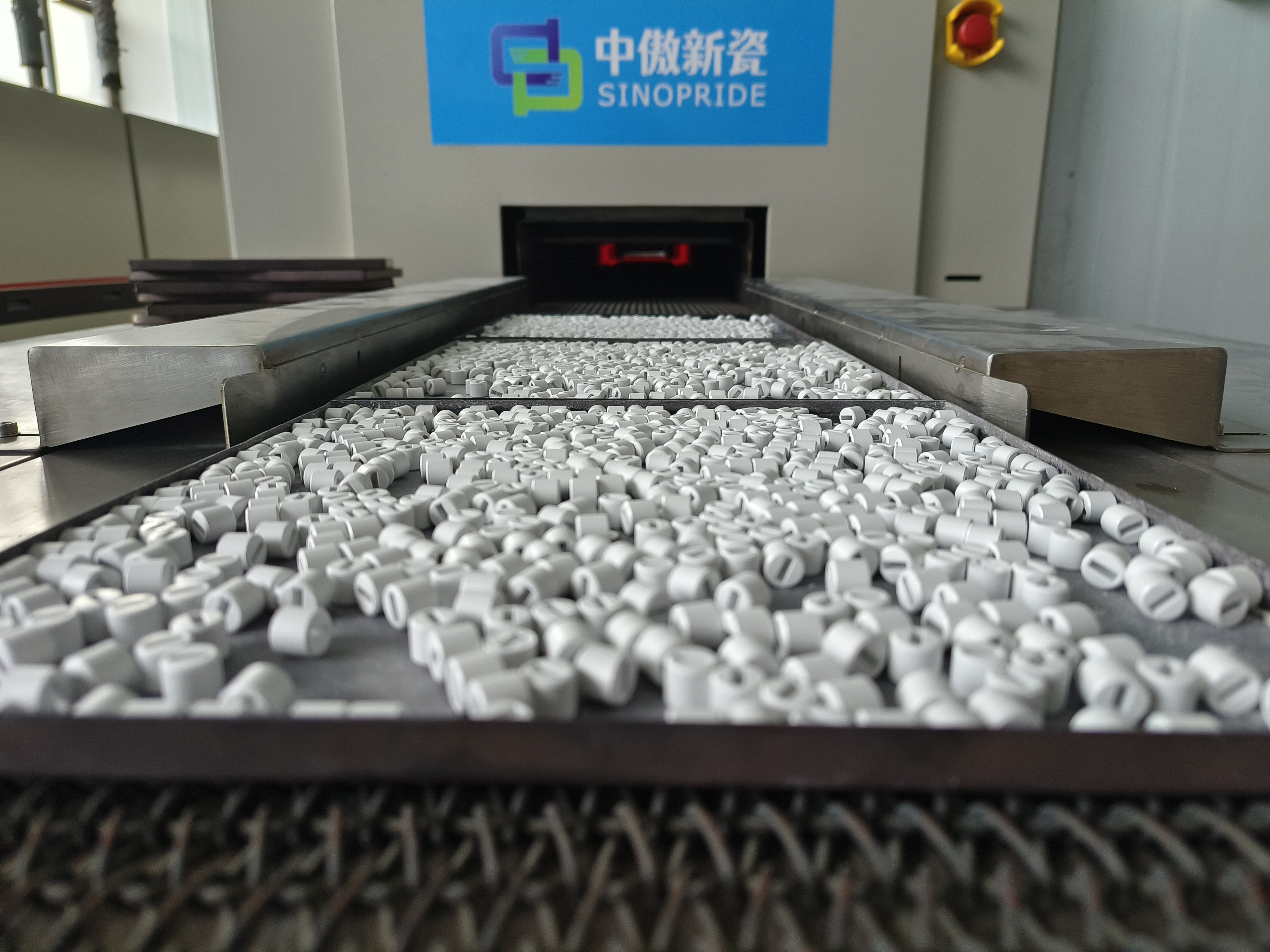

Glass Preform

A glass preform is a specially shaped piece of glass designed for use in hermetic sealing. The preform is typically used as a precursor to a final glass-to-metal seal, and it’s often customized to fit the specific geometry required for a particular application. Glass preforms are widely used in applications where the size and shape of the seal need to be tailored precisely. Their versatility makes them ideal for both low- and high-volume manufacturing.

What Are the Hermetic Solutions: Glass to Metal Seal?

Glass-to-metal sealing is a critical technology in a wide range of industries, from electronics and telecommunications to medical devices and space technology. These seals are designed to connect glass and metal materials, creating an airtight, waterproof, and durable bond that keeps sensitive components safe.

Benefits of Glass-Metal Sealing Solutions

Durability and Longevity: Glass-metal seals provide long-term protection for the sealed components. Their resilience against harsh environmental conditions, such as temperature fluctuations, moisture, and corrosive gases, makes them highly reliable over extended periods.

High Performance: Glass-metal seals ensure the safe and efficient operation of devices, maintaining the integrity of the inner components, even in extreme conditions. This is particularly important for electronics, aerospace, and medical devices where precision is critical.

Versatility: Glass-metal seals can be customized to meet a wide range of design requirements, making them suitable for many different applications. Whether you need a seal for a small sensor or a large piece of equipment, there’s a glass-metal sealing solution available.

Temperature Resistance: The hermetic seal formed between glass and metal offers excellent resistance to temperature fluctuations, making it ideal for industries with high or low-temperature requirements.

Leakage Prevention: A hermetically sealed glass-to-metal joint ensures that there are no leaks, preventing contamination or malfunction from external gases, liquids, or particles.

Customized Sealing Solutions

In many industries, off-the-shelf sealing solutions may not be sufficient for specific applications. This is where customized glass-to-metal sealing solutions come into play. Manufacturers can tailor seals to meet particular material specifications, size requirements, and environmental conditions. Whether it's for highly sensitive electronics or a rugged military-grade device, a custom hermetic seal ensures that the components inside remain protected, while the exterior remains impervious to the outside world.

2025 Glass to Metal Seal Manufacturers Recommendations

As the demand for hermetic sealing technology continues to grow, several companies stand out as leaders in the field, offering advanced materials and manufacturing techniques that meet the needs of 2025's evolving market.

1.Spcera: Spcera is a cutting-edge manufacturer of glass-to-metal seals, known for their commitment to high-quality, customizable sealing solutions. With a focus on precision and performance, Spcera offers a range of hermetic sealing options, including Kovar and iron-sealed glass, that meet the stringent demands of industries like aerospace, defense, and medical technology.

2.Specialty Glass: Specialty Glass is another leading player in the hermetic sealing market, offering specialized glass preforms and glass-to-metal sealing solutions. Their advanced manufacturing processes allow for rapid prototyping and production of high-precision glass seals.

3.Hermetic Seal Technologies: With decades of experience in glass-metal bonding, Hermetic Seal Technologies has become a trusted name for companies looking to integrate glass hermetic seals into their products. Their range of sealing materials and customization options ensures that they can meet any requirement, whether for military-grade applications or commercial electronics.

4.O’Fallon Glass: A trusted manufacturer of hermetically sealed components, O’Fallon Glass specializes in high-performance glass seals for use in extreme environments. Their glass-to-metal seals are used in applications ranging from satellites to medical implants.

Conclusion

The importance of hermetic sealing cannot be overstated, especially in industries where reliability, durability, and performance are non-negotiable. As the demand for these seals continues to grow, manufacturers like Spcera are at the forefront of developing advanced materials and solutions for the 2025 landscape. Whether you need Kovar seals for aerospace applications or iron-sealed glass for consumer electronics, the right hermetic seal can ensure your products stand the test of time.

In the world of high-performance components, a glass hermetic seal isn't just an option; it's a necessity. If you're looking for a reliable, high-quality glass-to-metal sealing solution, Spcera is a leading manufacturer that can provide you with customized sealing solutions tailored to your specific needs.

Recommended Reading

1.What does hermetically sealed mean?

2.What is Glass-to-Metal Hermetic Seals Solution:Hermetically sealed connectors

3.How to make hermetic seal:A Comprehensive Guide to Hermetic Solutions