What is Glass-to-Metal Hermetic Seals Solution:Hermetically sealed connectors

Release time:2025-09-03

In various industries, from aerospace to automotive, the reliability and longevity of connectors are paramount. One key technology that ensures these connectors perform under extreme conditions is glass-to-metal hermetic sealing. This advanced sealing solution guarantees that connectors are impervious to gases, moisture, and contaminants. In this blog post, we'll explore what hermetically sealed connectors are, their purpose, and why glass-to-metal hermetic seals are crucial for many applications.

what does hermetically sealed mean?

-what is hermetically sealed?

-What is the difference between hermetically sealed and sealed?

-What is a hermetically sealed connector?

What is the purpose of a hermetic seal?

-Best kovar sealing glass for rectangular connectors

-Oxygen sensor gaskets used in automotive nitrogen oxide sensors

Explore Types of Glass-to-Metal Hermetic Seals

-Glass-to-Glass Hermetic Seals

-Glass-to-Metal Hermetic Seals

-Ceramic-to-Metal Hermetic Seals

-Glass-ceramics-to-metal seals

Glass to Metal Seal Manufacturers:Custom Glass to Metal Sealed Connector

Conclusion

What Does Hermetically Sealed Mean?

The term "hermetically sealed" refers to a sealed system that is airtight, preventing any form of leakage or the ingress of gases, liquids, or contaminants. Hermetic seals are particularly important in situations where maintaining a controlled internal environment is critical, such as in high-performance electrical connectors or sensitive electronic devices.

These seals often use specialized materials and techniques, such as the combination of glass and metal, to ensure an airtight and durable seal. Unlike standard seals, which may simply prevent physical leakage, hermetic seals provide a far more robust barrier against environmental factors like moisture, pressure, and chemical exposure.

What Is Hermetically Sealed?

A hermetically sealed component is one that has been designed and constructed in a way that it creates a permanent, airtight seal. This type of seal ensures that the internal components or systems are protected from external environmental influences. Hermetic seals are typically made using glass and metal materials, which when fused together at high temperatures, form a strong bond that withstands a variety of conditions.

Hermetically sealed connectors are designed to be particularly useful in extreme conditions where traditional sealing methods may fail. These environments include high temperatures, varying pressure levels, and exposure to harmful chemicals or radiation.

What Is the Difference Between Hermetically Sealed and Sealed?

While both "hermetically sealed" and "sealed" connectors aim to prevent leakage, there are key differences between the two.

Sealed Connectors: These connectors may use materials like rubber or plastic to create a barrier against external elements. They are typically designed to prevent basic contaminants, but they may not offer a full airtight seal. Sealed connectors are suitable for less demanding applications where total protection from external elements isn't critical.

Hermetically Sealed Connectors: In contrast, hermetically sealed connectors use more advanced materials, like glass-to-metal seals, that form a permanent, airtight bond. These connectors are specifically designed to protect against even the most extreme environments, including high pressure, temperature variations, moisture, and chemicals.

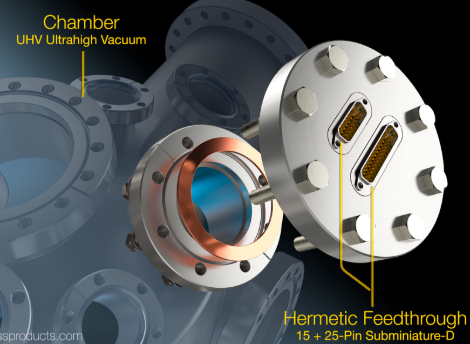

What Is a Hermetically Sealed Connector?

A hermetically sealed connector is a type of electrical connector that uses glass-to-metal hermetic sealing technology to ensure a highly secure, airtight environment. These connectors are commonly used in industries that require utmost reliability, such as aerospace, military, medical, and automotive sectors.

The glass-to-metal hermetic seal in these connectors provides several benefits, including:

Longevity: Hermetically sealed connectors are known for their durability, even in the harshest environments.

High Resistance: These connectors offer high resistance to environmental factors like high temperatures, moisture, and pressure.

Electrical Performance: They maintain superior electrical performance due to the airtight seal that protects internal components from contaminants that could affect their function.

What Is the Purpose of a Hermetic Seal?

The primary purpose of a hermetic seal is to protect sensitive internal components from external factors such as moisture, dust, gases, and extreme temperatures. This is particularly important in applications where failure could result in catastrophic outcomes, such as in spacecraft, military equipment, or medical devices.

By providing an airtight seal, hermetic connectors maintain the integrity and functionality of electrical circuits and ensure that they continue to perform optimally, even under extreme conditions. Some specific purposes of hermetically sealed connectors include:

Best Kovar Sealing Glass for Rectangular Connectors

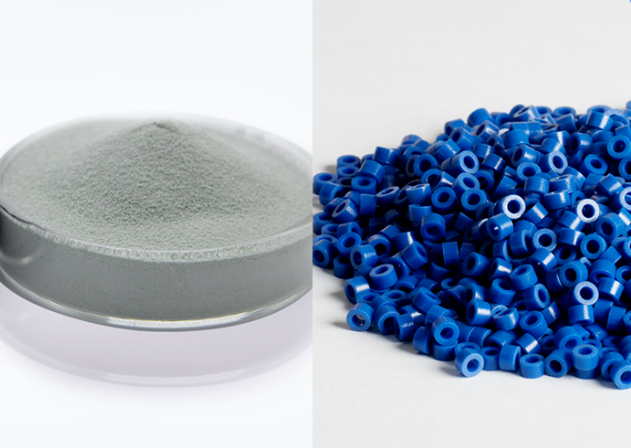

Kovar is a widely used metal in hermetic sealing, known for its similar thermal expansion coefficient to that of glass. This makes it ideal for creating hermetic seals, especially in rectangular connectors. The combination of Kovar and specialized sealing glasses ensures that these connectors maintain their integrity even in applications where extreme temperature fluctuations occur.

When choosing the best Kovar sealing glass for rectangular connectors, manufacturers often rely on glass compositions that bond tightly to Kovar, forming a strong and reliable seal. The use of Kovar also prevents the connector from being damaged by thermal cycling, which is a common issue in environments where temperature fluctuates rapidly.

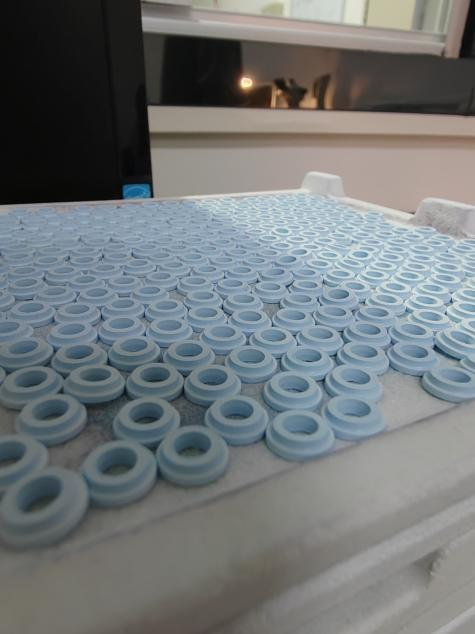

Oxygen Sensor Gaskets Used in Automotive Nitrogen Oxide Sensors

In the automotive industry, oxygen sensors and nitrogen oxide (NOx) sensors are essential components for controlling emissions and ensuring vehicle efficiency. These sensors must remain free of contamination to function accurately and efficiently. Glass-to-metal hermetic sealing solutions are used in the gaskets of these sensors to ensure that moisture, gases, and other contaminants don't enter the sensor housing and interfere with its performance.

By using hermetically sealed connectors in automotive applications, manufacturers can ensure the longevity and accuracy of their sensors, which are critical for meeting environmental regulations and improving vehicle performance.

Explore Types of Glass-to-Metal Hermetic Seals

Glass-to-metal hermetic sealing is a versatile technology that can be customized for various applications. There are different types of glass-to-metal hermetic seals, each designed to meet specific requirements in terms of strength, resistance, and application.

Glass-to-Glass Hermetic Seals

Glass-to-glass hermetic seals are typically used in applications where a high degree of chemical resistance is required. This type of seal uses two glass components that are fused together at high temperatures to create an airtight seal. These seals are common in optical or medical applications where the internal components need to be protected from the external environment.

Glass-to-Metal Hermetic Seals

The most common type of hermetic seal used in connectors is the glass-to-metal seal. In this design, the glass forms a strong, permanent bond with metal parts, typically made from materials like Kovar or stainless steel. These seals are particularly suited for applications where high durability and resistance to extreme environments are essential.

Ceramic-to-Metal Hermetic Seals

Ceramic-to-metal hermetic seals offer high electrical insulation properties and are commonly used in high-power applications. These seals are ideal for devices that need to withstand high voltage or that operate in environments requiring both physical and electrical isolation. The ceramic material provides excellent heat resistance and electrical performance.

Glass-Ceramics-to-Metal Seals

Glass-ceramic-to-metal seals combine the benefits of glass and ceramics to offer a highly durable, high-performance sealing solution. These seals are often used in advanced industrial or military applications, where performance in extreme environments is critical. The glass-ceramic bond provides superior strength, temperature stability, and resistance to corrosive substances.

Glass-to-Metal Seal Manufacturers: Custom Glass-to-Metal Sealed Connectors

The demand for custom glass-to-metal sealed connectors is growing, as industries require connectors that meet specific operational and environmental requirements. Many manufacturers now specialize in producing custom hermetically sealed connectors tailored to the needs of individual applications. These custom solutions ensure that connectors perform optimally in environments with extreme temperatures, high pressure, or exposure to harsh chemicals.

When selecting a manufacturer for custom hermetically sealed connectors, it's important to choose one that offers expertise in glass-to-metal sealing technology, as well as a proven track record of delivering high-quality, reliable products. Spcera customized hermetic sealing solutions can be designed for various types of connectors, including circular, rectangular or special structures, providing a high degree of flexibility to meet the needs of different industries.

Conclusion

Glass-to-metal hermetic sealed connectors are indispensable for applications that require high reliability in extreme environments. These connectors are designed to ensure the protection of sensitive components from environmental factors such as temperature fluctuations, moisture, and chemicals. By offering airtight, durable seals, hermetically sealed connectors play a crucial role in industries like aerospace, automotive, and medical equipment, where precision and performance are paramount.

As technology continues to advance, the demand for customized glass-to-metal hermetic sealed connectors will only increase. By working with specialized manufacturers, businesses can ensure they get the most suitable solution for their specific needs, guaranteeing long-lasting performance and reliability in critical applications.

Recommended reading :

1.What does hermetically sealed mean?