The Cornerstone of Global Industrial Sealing: A Deep Dive into Sinopride Glass Powder Solutions

Release time:2025-06-23

The article introduces the classification and core characteristics of glass powder and the key process of glass-metal sealing.

1. Introduction: Sealing Technology – the "Unsung Hero" of Industrial Progress

In the complex world of modern industry, from aerospace to electric vehicles, medical devices to consumer electronics, countless critical components must operate stably under extreme conditions such as high temperatures, high pressures, corrosive environments, or vacuums. In these challenging scenarios, a "invisible" yet vital technology – reliable sealing solutions – serves as the "invisible guardian" ensuring long-term stable operation, preventing leaks, and protecting internal precision components . Breakthroughs in sealing technology, particularly the application of glass powder, are profoundly transforming the landscape of modern industry, driving the miniaturization, high integration, high performance, and long lifespan of products .

As a leader in the field of special inorganic materials, Sinopride (www.spcera.net) focuses on providing high-performance glass powder solutions to empower industrial customers worldwide . This article delves into the classification, core characteristics, and key glass-to-metal sealing processes of glass powder, and details how Sinopride, with its deep accumulation in low melting point glass powder, high-temperature glass sealing powder, iron sealing glass powder, Kovar sealing glass, and phosphate glass, provides excellent sealing solutions for various industries. Meanwhile, we offer a practical purchasing guide for global buyers to help them make informed choices and ensure project success.

2. Classification and Core Characteristics of Glass Powder

Glass powder, as a specially formulated and finely processed glass material, boasts a core feature: its ability to soften and flow at specific temperatures, enabling tight sealing between materials . Classified by sintering temperature, chemical composition, and application scenarios, glass powder can be broadly divided into several categories, each with unique properties and advantages .

Low Melting Point Glass Powder: The Ideal Choice for Heat-Sensitive Components

Low Melting Point Glass Powder softens and flows at temperatures far lower than traditional glass, enabling tight sealing between materials . This characteristic makes it an ideal choice for sensitive components and materials that cannot withstand high temperatures, effectively avoiding damage to components from high-temperature processes . Sinopride's LC-1 model low melting point glass powder, belonging to the bismuthate system, has a sintering temperature of 500–530°C and a thermal expansion coefficient of 11.0×10−7/K . It exhibits excellent fluidity and bonding ability, forming highly reliable, hermetically sealed layers with various materials such as glass, ceramics, metals, and semiconductors .

Notably, the lead-free nature of LC-1 aligns with global environmental trends and supports green certification for end products . Its application in low-temperature sealing of vacuum insulated cups significantly enhances product vacuum degree and heat preservation effect .

High-Temperature Glass Sealing Powder: The Resilient Choice for Extreme Environments

High-temperature glass sealing powder is designed as a sealing material for critical components operating in harsh environments such as high temperatures, high pressures, corrosive conditions, or vacuums . This type of glass powder can sinter at 920–980°C, forming a strong bond with metals like iron and Kovar alloy (4J29) . Its main advantages include:

• Thermal Expansion Matching: Precisely adjusted coefficients ensure synchronous expansion with metals, minimizing stress cracks .

• Extreme Condition Resistance: Maintains airtightness at temperatures up to 500°C and resists chemical corrosion .

• Electrical Insulation Performance: Provides high resistance (DC 500V > 500MΩ) in electronic applications .

Sinopride offers comprehensive high-temperature glass sealing powder solutions, including iron sealing glass and Kovar sealing glass, which have passed ISO 9001 and IATF 16949 certifications and perform excellently in extreme environments .

Phosphate Glass: The Future-Oriented Choice Balancing Environmental Friendliness and Performance

Phosphate Glass is a special glass with pentoxide (P₂O₅) as the main network former . Compared with traditional silicate glass, it has a unique chemical structure and physical properties, showing great application potential in the field of low-temperature sealing . Sinopride has developed phosphate glass powder specifically for low-temperature sealing applications, offering the following advantages:

• Excellent Chemical and Thermal Stability: Stable structure resists chemical erosion and maintains performance over a wide temperature range .

• Adjustable Thermal Expansion Coefficient: The coefficient (CTE) can be precisely regulated to perfectly match metal materials like stainless steel, a key to forming firm, stress-free, and airtight seals .

• Inherent Environmental Friendliness: The formula is completely free of harmful heavy metals such as lead and cadmium, 100% compliant with the world's strictest environmental standards, clearing obstacles for product exports .

3. Glass-to-Metal Sealing: A Key Process in Modern Industry

Glass-to-metal sealing is a complex engineering process that fuses glass and metal components together to form a sealed and highly integrated connection . Unlike adhesive or mechanical seals, this technology relies on thermal and chemical compatibility, making it essential for applications where catastrophic consequences may occur .

Principles of Glass-to-Metal Sealing

The core of this process depends on:

• Thermal Expansion Matching: Ensures glass and metal expand/contract at similar rates to avoid stress-induced fractures .

• Chemical Adhesion: Forms a strong interface through oxidative layer interaction during sintering .

• Environmental Tolerance: Withstands extreme temperatures, pressures, and corrosive media .

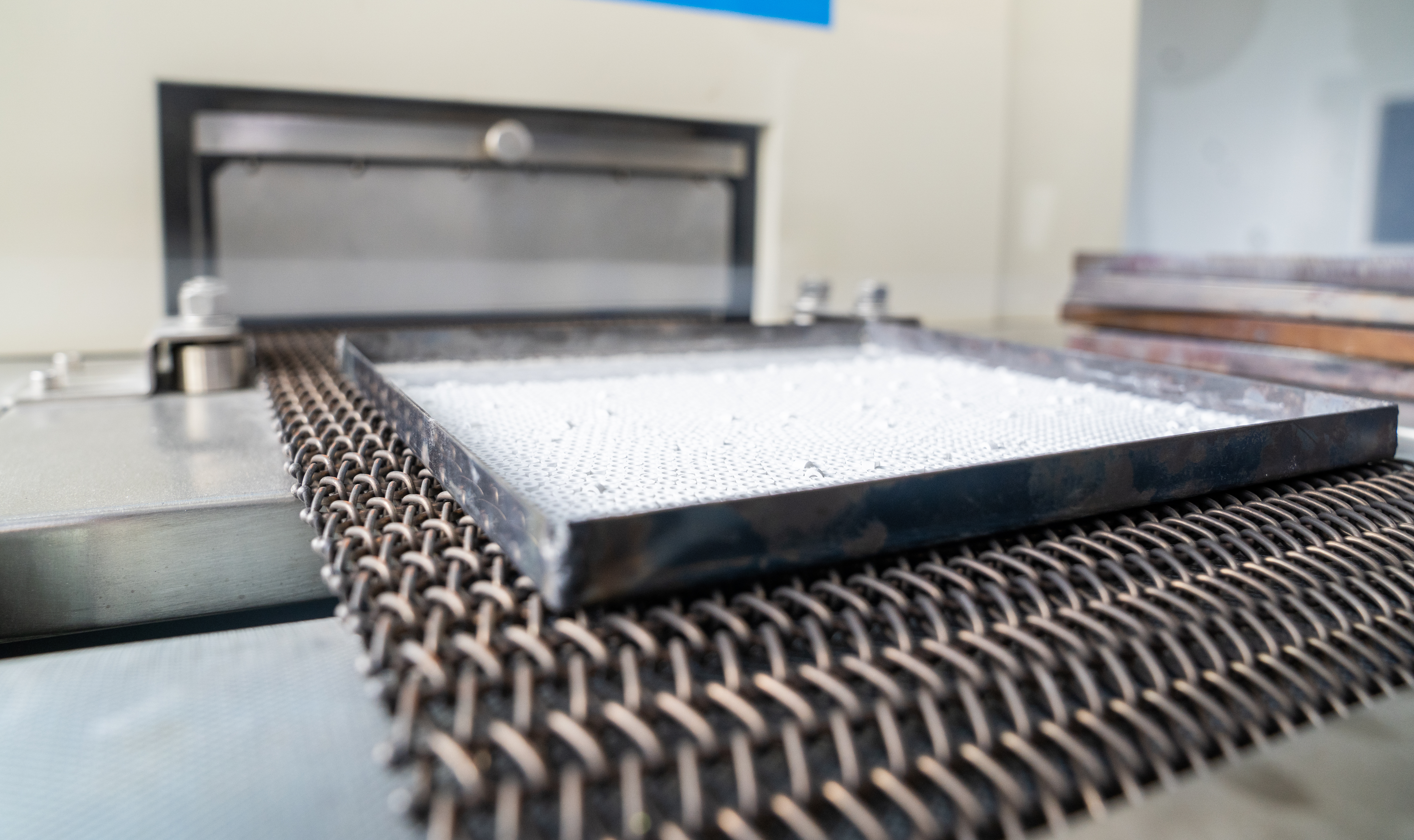

Key Process Parameters

• Component Preparation: Metals are cleaned and etched; glass powder is screened by particle size .

• Glass Application: Powder is coated onto the metal surface via screen printing or dispensing .

• Sintering: Glass is heated and melted in a controlled atmosphere to form a bond (temperature ranges from 500 to 980°C depending on materials) .

• Cooling: Gradual cooling minimizes thermal stress; annealing improves durability .

• Testing: Helium leak detection and mechanical tests ensure air tightness and strength .

4. Sinopride Core Products: Empowering Diverse Application Scenarios

With deep industry experience and independent R&D capabilities, Sinopride provides customers with two major categories of high-performance glass powder products: iron sealing glass and Kovar sealing glass, as well as low-temperature glass powder and LTCC dielectric glass materials. These products are carefully designed and strictly tested to ensure optimal performance in their respective application scenarios .

Iron Sealing Glass Powder: The Sealing Expert for High-Voltage, High-Temperature, and Strong Corrosion Environments

Sinopride 's Iron Sealing Glass Powder is designed for applications requiring sealing with iron-based metals (such as carbon steel, stainless steel, etc.) . This sealing glass powder product is renowned for its excellent resistance to high voltage, high resistance, high temperature, and strong corrosion environments .

• High-Voltage Environments: In power transformers and high-voltage switchgear, Sinopride 's iron sealing glass powder (such as ST015, ST408) forms a high-resistance sealing layer, effectively preventing leakage and improving equipment efficiency and safety . For example, the ST015 model forms a glass sealing layer with a resistivity > 500 MΩ between copper windings and the iron core, effectively preventing leakage risks .

• High-Temperature Environments: Components of aero-engines (such as turbine blades and combustion chambers) and industrial furnace seals require materials that can withstand extremely high temperatures . The SH604 model iron sealing glass powder has a low thermal expansion coefficient, resists thermal shock, and achieves long-term stable sealing in aero-engines and industrial furnaces .

• Strong Corrosion Environments: In chemical processing equipment (such as pipelines in sulfuric acid production plants) and marine applications, Sinopride's iron sealing glass powder (such as SH604) has high chemical stability, resisting strong acids, alkalis, and salt spray corrosion, protecting the underlying metal and ensuring safe and efficient equipment operation .

Kovar Sealing Glass: Precision Matching to Eliminate Stress

Kovar sealing glass is another star product of Sinopride, developed specifically for perfect thermal expansion coefficient matching with Kovar metal 4J29 . This precise matching is the key to achieving stress-free sealing, ensuring that glass and metal expand and contract synchronously under extreme temperature changes, thus minimizing stress generated during sealing .

• Relays: In automotive power relays and industrial relays, Sinopride's SK016 Kovar sealing glass, through thermal matching with the 4J29 metal base, maintains excellent sealing performance during extreme temperature cycles, enhancing product reliability .

• TO Headers: In semiconductor packaging, such as TO-254 packaging for IGBT modules and TO-8 packaging for pressure sensors, Kovar sealing glass provides electrical insulation and airtightness guarantees .

• Crystal Oscillators: Oven-Controlled Crystal Oscillators (OCXO) and automotive-grade crystal oscillators have extremely high requirements for frequency stability. The low thermal expansion coefficient and strong bonding force of Kovar sealing glass ensure that crystal oscillators remain stable in wide temperature and vibration environments .

Low-Temperature Glass Powder: Driving Product Miniaturization and Performance Enhancement

In addition to high-temperature and Kovar sealing glass, Sinopride's low melting point glass powder also plays a key role in driving product miniaturization and performance enhancement . Its ability to seal at lower temperatures means it can integrate with a wider range of materials, including heat-sensitive ones, which is crucial for the miniaturization of electronic products and the development of advanced sensors .

• Vacuum Insulated Cups: Sinopride's LC-1 model low-temperature glass powder demonstrates excellent performance in low-temperature sealing of vacuum insulated cups, significantly improving product vacuum degree and heat preservation effect .

• Sensitive Component Sealing: In the electronics industry, low-temperature glass powder is widely used in the sealing and packaging of sensors, integrated circuits, and vacuum packages, effectively protecting these sensitive components from moisture, dust, and pollutants, ensuring their long-term stable operation .

LTCC Technology and Glass Powder: Empowering Next-Generation Electronic Products

Low-Temperature Co-fired Ceramic (LTCC) technology is key to achieving highly integrated, high-performance electronic packaging . Sinopride provides comprehensive sealing glass powder solutions, including Kovar sealing glass and iron-based sealing glass, customized for robust glass-to-metal sealing applications. These products are crucial for ensuring the long-term reliability and performance of electronic packages, especially those using LTCC technology .

5. Sinopride's Technical Leadership and Competitive Advantages

As a global leader in sealing, Sinopridestands out for its deep technical accumulation, excellent R&D capabilities, strict quality control, and customer-centric customized services .

Exceptional R&D Soft Power: Technical Genes and Innovation Barriers

Sinopride's R&D team is led by two core doctors, building a technical matrix with both academic depth and industrial implementation capabilities .

• Top R&D Team: Dr. Miao Xigen (R&D Director, Ph.D. in Metallurgy and Materials from the University of Birmingham, UK, Postdoctoral Fellow in Advanced Ceramic Materials at the University of Sheffield, leading national "863" scientific research projects, researching over 10 material systems including sealing glass and microwave ceramics) and Dr. Shen Liang (Executive Deputy General Manager, Ph.D. in Materials and Chemistry from Sun Yat-sen University, focusing on research and development of metal sealing glass and sodium-ion battery sealing materials) together lead 11 R&D personnel with professional backgrounds covering material physics, ceramic technology, electrochemistry, and other fields, forming end-to-end technical capabilities from formula design to application verification .

• Patents and Intellectual Property: A total of 128 invention patents (42 authorized) and 8 PCT international patents have been applied for, covering core technologies such as low-temperature sealing glass and SH604 glass for lithium thionyl chloride battery caps . Among them, bismuth-based low-temperature glass has achieved substitution for lead-containing materials .

Strong R&D Hard Power: Equipment Level and Mass Production Scale

• Full-chain Production Equipment: A complete production line covering "melting-ball milling-granulation-molding-sintering" has been built, with 15 crucible melting furnaces + 1 continuous melting furnace (daily output 1,700–2,000 kg), 8 horizontal ball mills (powder grinding to below 10μm, daily processing 1,000–1,500 kg), 2 production granulation towers + 1 experimental tower (daily granulated powder 1,500 kg), and a total of 33 molding equipment, with a monthly output of 20 million glass blanks .

• Testing Instruments: Equipped with more than 20 types of testing equipment such as laser particle size analyzers, helium leak detectors, electron microscopes, and universal testing machines, achieving precise control of more than 10 core indicators such as thermal expansion coefficient and airtightness .

• Large-scale Mass Production Capacity: 3 sealing glass granulated powder production lines (monthly output 100 tons), 7 metal-glass sealing production lines, and a monthly capacity of over 100 million glass blanks, suitable for large-scale application scenarios such as automotive sensors and lithium battery caps .

Strict Quality Control System

Sinopride adopts a triple mechanism for quality control of powder glass sealing, ensuring consistency from glass formula to finished product and effectively avoiding performance "batch fluctuations" .

• Raw Material Traceability: Each batch of raw materials undergoes ICP-MS analysis, controlling the content error of Al, B, Zn to ensure silicon source purity, and providing RoHS/REACH compliance reports .

• Powder Stage Control: Supports customized powder glass coating as needed, with wet spray coating treatment to improve fluidity and adhesion .

• Factory Stage: 100% batch inspection mechanism, including DSC analysis and dilatometer testing. For customized glass-to-metal sealing orders, complete sealing performance simulation reports are provided .

Customer-Centric Customized Services

Sinopride understands that each application has unique needs, so it provides comprehensive customized services .

6. Purchasing Guide for Industrial Sealing Glass Powder: Key Considerations for Informed Choices

For buyers and technical teams in aerospace, electric vehicles, and electronics, choosing the right sealing glass powder boils down to one question: does it meet the temperature, material, and reliability requirements of my application? .

Starting from Application Requirements: Temperature, Material, and Environment

1. Operating Temperature Range:

◦ Low-temperature Applications (-60°C to 200°C): Suitable for electric vehicle batteries, consumer electronics, and medical devices. Phosphate glass is the ideal choice, with a sealing temperature below 380°C .

◦ Medium-temperature Applications (200°C to 500°C): Suitable for automotive sensors, industrial machinery, and household appliances. Aluminoborate glass performs excellently, providing thermal stability over a wider temperature range (420–480°C) .

◦ High-temperature Applications (>500°C): Suitable for aero-engines, high-voltage transformers, and industrial furnaces. Customized glass-ceramic composites are the first choice .

1. Sealing Materials: The golden rule of sealing is to match the thermal expansion coefficient (CTE) of the glass powder with the substrate .

◦ Aluminum Alloy: Thermal expansion coefficient 23×10−6/K, recommended phosphate glass, CTE matching range 72–78×10−7/K .

◦ Kovar Alloy: Thermal expansion coefficient 5.0×10−6/K, recommended aluminoborate glass, CTE matching range 45–55×10−7/K .

1. Environmental Pressure: Seals must withstand the "daily wear and tear" of the application .

7. Conclusion: Join Hands with Sinopride to Create a New Future of Sealing

Low Melting Point Glass Powder, as a disruptive material, is profoundly changing the sealing landscape of modern industry . It not only provides excellent sealing performance and material compatibility but also demonstrates great advantages in environmental protection and cost-effectiveness . With its deep professional accumulation, leading R&D strength, strict quality control, and large-scale production capacity, Sinopride has become a leader in this field .

Sinopride's LC-1 model low-temperature glass powder, with its lead-free environmental protection, excellent performance, and wide application potential, provides reliable solutions for multiple industries such as electronics, automotive, medical, and vacuum insulation . Choosing Sinopride means choosing a reliable partner that can provide high-quality products, customized services, and professional technical support . Sinopride is committed to becoming a Chinese pride in the field of special glass and new ceramics, contributing to promoting the innovation and development of materials science .

We sincerely invite you to visit Sinopride (www.spcera.net)'s official website to learn more about our product range or directly contact our expert team to explore how advanced glass powder solutions can help your projects succeed.

Related Content for your reference

Kovar Sealing Glass and Iron Sealing Glass products

(https://www.spcera.net/kovar-sealing-glass.html)

Powder Glass Sealing in Vacuum and High-Temperature Environments

(https://www.spcera.net/powder-glass-sealing-in-vacuum-and-high-temperature-environments.html)