How Glass Powder Enhances the Durability of Compressor Terminals?

Release time:2025-08-18

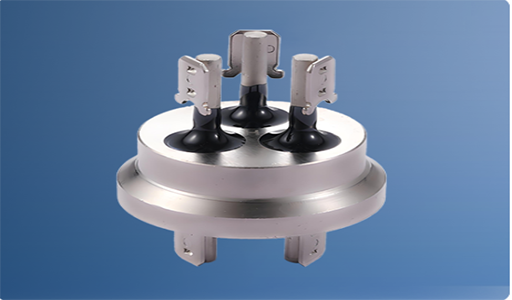

In modern household appliances, compressor terminals are key components that connect the compressor to the electrical system, ensuring the stability and reliability of the electrical connection. The performance of compressor terminals directly affects the operation and lifespan of the equipment. Terminals are prone to damage under high temperatures, overloading, and other conditions, leading to equipment failure. To enhance the durability of compressor terminals, glass powder (particularly the ST015A sealing powder) is widely used, as it effectively improves the electrical stability, high-temperature resistance, and corrosion resistance of the terminals. This article will explore the definition of compressor terminals, common issues, and how glass powder improves their durability.

What Causes Compressor Terminals to Burn Out?

Compressor terminal burnout is a common equipment failure, caused by several factors:

Overcurrent: When the compressor operates beyond its design current capacity, overcurrent can cause the terminal to overheat, deform, or burn out.

Poor Electrical Contact: If the terminal and cable connection is not secure, localized heat buildup may occur as current flows, leading to terminal overheating or burnout.

Excessive Operating Temperature: When the compressor operates in high-temperature environments, the terminal expands due to heat, which can damage insulation and lead to short circuits or burnout.

Corrosion: If the terminal is exposed to moisture or corrosive substances in the air, oxidation or corrosion may occur, increasing contact resistance, reducing conductivity, and leading to terminal burnout.

Improper Installation: If the terminals are improperly connected, loose, or misaligned, it can cause unstable current flow, increasing the risk of burnout.

Specific Example: Burnout of Air Compressor Terminals

In appliances like air conditioners and refrigerators, one common failure is terminal burnout. For example, in air conditioner compressors, terminals may burn out due to excessive current or prolonged operation in high-temperature environments. This can lead to the compressor malfunctioning, which impacts the cooling performance of the air conditioner.

Compressor Terminal Repair

When a compressor terminal burns out or encounters other issues, repair or replacement is usually required. The repair process generally involves checking the extent of terminal damage, cleaning corrosion, replacing damaged terminals, and reconnecting the cables. Additionally, using high-quality sealing materials (such as glass powder) for terminal sealing can effectively enhance the durability of the terminals.

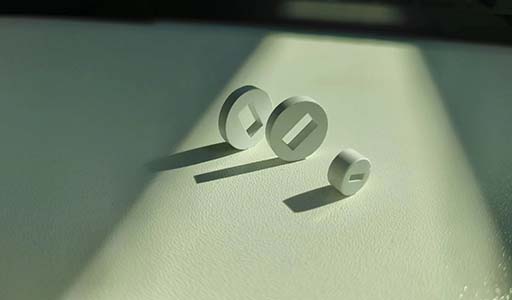

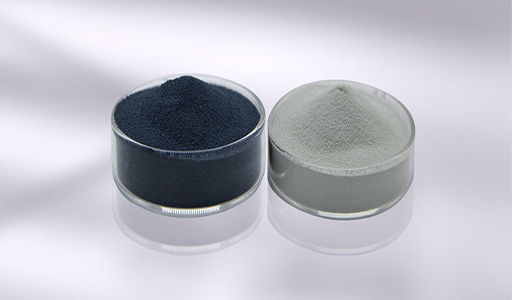

Characteristics of Glass Powder

Glass powder is a fine material made from processed glass, possessing a variety of excellent properties. As a sealing material, it is commonly used to improve electrical contact and enhance the durability of terminals.

Insulation Properties

Glass powder has excellent insulating properties. It effectively isolates electrical currents, preventing short circuits or leakage between terminals, ensuring the normal operation of compressors. Especially in humid or high-temperature environments, the insulating ability of glass powder helps reduce the risk of electrical failures.

High-Temperature Resistance

Glass powder can withstand temperatures of up to several hundred degrees Celsius, making it particularly effective in high-temperature environments. Compressor terminals often operate under high-load conditions, causing the contact surfaces to heat up. The use of glass powder significantly improves the high-temperature resistance of terminals, reducing the risk of burnout due to excessive heat.

Corrosion Resistance

Due to its strong corrosion resistance, glass powder effectively protects the contact surfaces of terminals from environmental corrosion, especially in humid or saline conditions. Even when exposed to these harsh environments for extended periods, glass powder maintains its excellent performance, preventing electrical failures caused by corrosion.

(h3)Environmental Friendliness

Glass powder is a non-toxic, harmless material that does not cause environmental pollution. Therefore, using glass powder to seal compressor terminals not only improves the durability of the equipment but also meets modern environmental protection standards.

The Role of Glass Powder in Compressor Terminals

Features of ST015A Sealing Powder

Glass powder, particularly ST015A sealing powder, is a high-performance sealing material. It is made from high-quality glass powder, chemical additives, and binders, and is widely used in compressor terminal sealing. The ST015A sealing powder has the following characteristics:

Excellent Electrical Insulation: Effectively isolates the electrical current to prevent leakage and ensures the safe operation of the compressor.

High-Temperature Resistance: Capable of withstanding high-temperature environments, preventing terminal damage or burnout due to excessive heat, and meeting the compressor's high-temperature operating requirements.

Corrosion Resistance: Effectively prevents moisture and corrosive substances from damaging the terminals, ensuring long-term stable operation.

Enhanced Mechanical Strength: Increases the terminal’s resistance to compression and wear, reducing the risk of damage from external forces.

Specific Example:

ST015A Sealing Powder Widely Used in Various Air Conditioner Compressor Terminals and Refrigerator Compressor Terminals .ST015A sealing powder is widely used in sealing the terminals of air conditioner compressors and refrigerator compressors. For instance, when sealing the terminal of an air conditioner compressor, ST015A sealing powder bonds well with the terminal, providing excellent electrical insulation and high-temperature resistance, which prolongs the life of the compressor terminal. Its performance is comparable to that of imported sealing glass powders from Japan, the U.S., and other countries, making it an ideal material for sealing the terminals of both domestic and international air conditioner and refrigerator compressors.

Widespread Applications of Glass Powder

In addition to sealing compressor terminals, glass powder has found widespread applications in various fields.

In the power industry, glass powder is commonly used as an insulating material for electrical equipment. Its excellent insulation properties and high-temperature resistance enable it to provide reliable protection in high-voltage and high-temperature working environments

High-Performance Ceramics

Glass powder also plays a significant role in the production of high-performance ceramics. It enhances the strength, wear resistance, and thermal stability of ceramic materials, making it widely used in industries such as aerospace and automotive.

Home Appliances

Apart from sealing compressor terminals, glass powder is also used in other components of home appliances, such as electric water heaters and washing machines. By enhancing the products' high-temperature resistance and corrosion resistance, glass powder improves the overall performance and lifespan of home appliances.

Compressor terminals are vital components for ensuring the normal operation of household appliances, but they are susceptible to failure due to overcurrent, high temperatures, poor contact, and other factors. The use of glass powder, particularly ST015A sealing powder, can significantly enhance the durability of the terminals by improving their electrical stability, high-temperature resistance, and corrosion resistance, thereby reducing the risk of burnout. For compressor terminal sealing and repair needs, Sinopride Brand provides high-quality ST015A sealing powder to help extend the lifespan of equipment and ensure the stable operation of compressors. Choose Sinopride Brand’s sealing materials for the best protection and performance for your devices.