Why Glass-to-Metal Seal Solutions Are So Important for Implantable Medical Devices?

Release time:2025-09-28

Glass-to-metal hermetic seals are an essential technology for implantable medical devices, providing a durable, airtight, and watertight seal to protect sensitive electronics from moisture, gases, and contaminants. These seals offer significant advantages over alternatives like ceramic-to-metal, polymer, and epoxy seals, including better flexibility, biocompatibility, and resistance to extreme conditions. Glass-to-metal seals play a vital role in ensuring the long-term reliability of devices such as pacemakers, neurostimulators, and hearing aids. As medical devices continue to evolve, the demand for smaller, more reliable seals will increase, and advancements in materials science will enhance their performance.

What Is a Glass-to-Metal Hermetic Seal Solution?

What Is the Main Role of Glass-to-Metal Seals in Implantable Medical Devices?

Advantages of Glass-to-Metal Seals Over Alternative Materials

-Glass to metal hermetic seals vs. Ceramic-to-metal seals

-Glass to metal sealing vs. Polymer seal

-Glass-to-metal seal vs. Epoxy seal

How to Choose the Right Glass-to-Metal Seal Manufacturer

Future Application Trends of Glass-to-Metal Sealing Solutions

Why Choose Spcera Seals as Your First Choice

-Provide customized sealing solutions

-Advanced sealing glass materials

-Steatite ceramics with high electrical insulation

FAQs

-How do glass-to-metal solutions help reduce the cost of implantable devices?

-What challenges exist in using glass-to-metal seals in implantable devices?

-Why are glass-to-metal seals used in implantable medical devices?

What Is a Glass-to-Metal Hermetic Seal Solution?

A glass-to-metal hermetic seal is a critical sealing technology that involves bonding glass to metal to create an airtight and watertight seal. This type of sealing is vital for medical devices, especially those that are implantable within the human body. The combination of glass and metal ensures that the sensitive electronics inside the device remain protected from moisture, gases, and other contaminants, which could compromise the device’s functionality or safety.

Glass-to-metal seals are designed to offer long-lasting durability, biocompatibility, and resistance to extreme temperatures and pressures, making them ideal for medical applications where reliability is paramount. These seals are used in a variety of devices, including pacemakers, neurostimulators, implantable pumps, and circuitry for hearing aids.

The sealing process involves fusing specially formulated glass to metals like stainless steel or Kovar, which are compatible with human tissue and bodily fluids. This bond is formed at high temperatures, ensuring a permanent, robust seal that prevents leakage and protects the sensitive electronics and components inside the device.

What Is the Main Role of Glass-to-Metal Seals in Implantable Medical Devices?

The primary role of glass-to-metal seals in implantable medical devices is to provide hermetic sealing, which ensures the protection of the internal components from the surrounding environment. Implantable medical devices are exposed to extreme conditions, such as fluctuating body temperatures, pressure, and various chemical elements present in bodily fluids. The hermetic seal formed by glass and metal prevents moisture, gases, and other potentially harmful substances from entering the device, ensuring that the device continues to function without malfunctions.

The hermetic seal provided by glass-to-metal technology is especially important in devices that require electrical insulation, such as pacemakers and neurostimulators. It also serves to maintain the sterility of the internal electronics, which is crucial for avoiding infections when the device is implanted in the body. Without this kind of protection, the device could fail, posing serious risks to patient health.

Advantages of Glass-to-Metal Seals Over Alternative Materials

While there are other sealing technologies available, glass-to-metal seals offer several advantages over alternatives such as ceramic-to-metal seals, polymer seals, and epoxy seals.

Glass-to-Metal Hermetic Seals vs. Ceramic-to-Metal Seals

Ceramic-to-metal seals and glass-to-metal seals share some similarities, as both provide strong, durable seals. However, glass-to-metal seals have several distinct advantages. For instance, glass-to-metal seals offer greater flexibility, which is beneficial for devices that need to be compact and lightweight. The thermal expansion coefficient (TEC) of glass can be adjusted to match that of the metal, providing excellent performance under temperature variations, an essential factor in medical device reliability.

On the other hand, ceramic-to-metal seals are often more brittle and can fail when exposed to thermal stress. They are generally better suited for environments requiring high mechanical strength but are less versatile compared to glass-to-metal seals in medical applications.

Glass-to-Metal Sealing vs. Polymer Seals

Polymer seals, like those made from rubber or plastic, are often used for less demanding applications due to their low cost and ease of manufacture. However, for implantable medical devices, polymers fall short in several key areas. They are prone to degradation over time, especially when exposed to body fluids or extreme conditions. This makes them unsuitable for long-term implantable medical devices.

Glass-to-metal seals, in contrast, are more durable, chemically resistant, and capable of withstanding extreme temperatures and pressure. They also offer better biocompatibility, ensuring that there are no harmful reactions when the device is in contact with human tissue.

Glass-to-Metal Seal vs. Epoxy Seal

Epoxy seals are commonly used in consumer electronics and other non-medical applications. However, epoxy is less suitable for implantable devices because it is vulnerable to chemical breakdown and moisture absorption, which can lead to failure over time. Epoxy seals also lack the electrical insulation properties necessary for medical devices like pacemakers and defibrillators.

In contrast, glass-to-metal seals are permanent and provide excellent electrical insulation, which is essential for devices that rely on electrical components. Additionally, glass is highly resistant to chemical reactions, making it ideal for the long-term operation of devices inside the human body.

How to Choose the Right Glass-to-Metal Seal Manufacturer

When choosing a manufacturer for glass-to-metal seals, especially for implantable medical devices, it is important to consider several key factors:

Experience in Medical Applications: Choose a manufacturer that has a proven track record in the medical industry. They should be familiar with the stringent requirements for biocompatibility, sterility, and long-term performance.

Customization Capabilities: Every implantable device is different, and a good manufacturer will offer customized sealing solutions that meet your device's specific needs in terms of size, shape, and material compatibility.

Quality Certifications: A reputable manufacturer should hold certifications such as ISO9001, ISO14001, and GJB9001C. These certifications demonstrate that the manufacturer follows international quality management and environmental standards, ensuring the highest quality and compliance with medical regulations.

Proven Track Record: Look for manufacturers with successful case studies or partnerships with leading medical device companies. A proven history of delivering high-quality seals will give you confidence in their ability to meet your requirements.

Future Application Trends of Glass-to-Metal Sealing Solutions

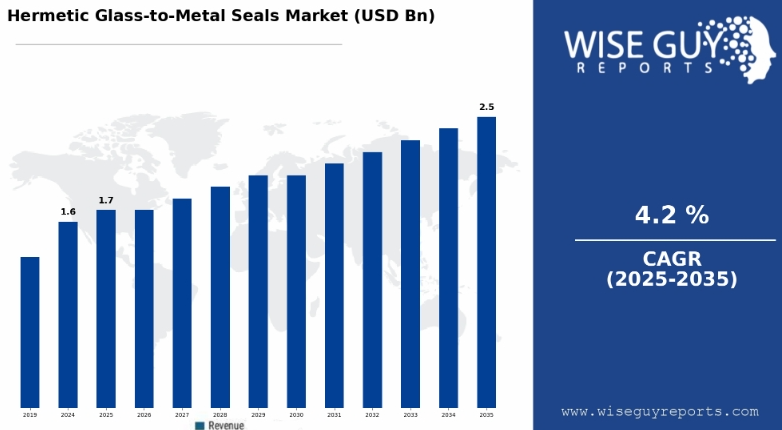

The future of glass-to-metal sealing solutions in the medical industry looks promising. As medical devices continue to evolve, miniaturization and complexity are key trends. Glass-to-metal seals are already being used in increasingly smaller devices, such as implantable sensors and drug delivery systems.

In addition, the advancements in materials science and manufacturing techniques will continue to make glass-to-metal seals more cost-effective, improving access to these solutions for a broader range of medical devices. This includes the use of new glass compositions that offer even better performance, such as enhanced resistance to body fluids or improved sealing properties at extreme temperatures.

Moreover, wireless medical devices and remote monitoring implants are driving the need for smaller, more durable seals. Glass-to-metal seals will play a critical role in ensuring the long-term reliability and performance of these devices.

Why Choose Spcera Seals as Your First Choice

Spcera Seals is a trusted manufacturer of glass-to-metal sealing solutions, offering ISO9001, ISO14001, and GJB9001C certifications, which guarantee high-quality production processes and adherence to international standards.

Provide Customized Sealing Solutions

Spcera Seals excels at providing customized sealing solutions designed to meet the unique needs of each medical device. Whether you're working with pacemakers, neurostimulators, or other implantable devices, Spcera ensures that the seals are perfectly tailored to your device’s requirements.

Advanced Sealing Glass Materials

Spcera uses advanced sealing glass materials such as SK016 for Kovar sealing. This glass composition has excellent thermal and electrical properties, making it perfect for medical applications. It can withstand temperatures of up to 980°C and provides superior electrical insulation. The different color options, including green, blue, white, and brown, provide flexibility for aesthetic and functional needs.

|

Glass Specifications & Applications |

||||||

|

Applications |

Code |

Glass |

Density |

Sintering |

TEC/10-6(30-300℃) |

Color |

|

Sealing for Kovar |

SK016 |

SiO2-Na2O-K2O |

2.254 g/cm3 |

970~980 Tm/℃ |

5.0±0.5 |

Green, Blue, |

This glass is ideal for sealing applications in high-precision environments where durability and electrical performance are paramount.

Steatite Ceramics with High Electrical Insulation

In addition to glass-to-metal seals, Spcera offers steatite ceramics for applications that require high electrical insulation, a critical property for devices like pacemakers and defibrillators.

FAQs

How Do Glass-to-Metal Solutions Help Reduce the Cost of Implantable Devices?

By offering long-term reliability, glass-to-metal seals reduce the need for replacements or repairs. This reduces overall operational costs and makes the devices more cost-effective in the long run.

What Challenges Exist in Using Glass-to-Metal Seals in Implantable Devices?

While glass-to-metal seals are highly reliable, they can be expensive to manufacture. Additionally, ensuring that the glass and metal materials expand at the same rate during temperature fluctuations is a key challenge for manufacturers.

Why Are Glass-to-Metal Seals Used in Implantable Medical Devices?

Glass-to-metal seals are crucial for providing hermetic sealing, biocompatibility, and electrical insulation, ensuring the device functions properly within the human body for an extended period.